Introduction

Choosing the right supplier is critical in plastic manufacturing. One wrong decision can lead to delays, quality failures, and financial loss. This practical guide explains how to verify a plastic mold parts manufacturers credibility using proven, real-world methods. Whether you are sourcing locally or internationally, these steps help you avoid risk and build long-term partnerships. Understanding how to verify a plastic mold parts manufacturers credibility also improves compliance, product quality, and brand trust.

Why Verifying Manufacturer Credibility Matters

Plastic mold parts play a vital role in automotive, medical, electronics, and consumer products. A credible manufacturer ensures consistent quality, precise tolerances, and reliable delivery timelines. Without proper verification, businesses face hidden costs, recalls, and reputation damage. Learning how to verify a plastic mold parts manufacturers credibility protects your investment and ensures smooth production.

Check Business Registration and Legal Presence

The first step to verify a plastic mold parts manufacturers credibility is confirming legal existence. A legitimate manufacturer will have registered business details, tax numbers, and export licenses. You should verify company registration through government or trade portals. Transparency in legal documentation reflects professionalism and accountability. Manufacturers who hesitate to share this information often raise red flags.

Evaluate Industry Experience and Track Record

Experience speaks louder than promises. When assessing how to verify a plastic mold parts manufacturers credibility, review how long they have operated and the industries they serve. A manufacturer with years of experience usually understands tooling complexities, material behavior, and quality standards. Ask for project examples that match your requirements. Consistent delivery over time signals reliability.

Review Certifications and Quality Standards

Certifications are a strong indicator of credibility. ISO 9001, ISO 14001, and ISO 13485 are common standards in plastic molding. These certifications show structured quality control systems. Verifying certification numbers with issuing bodies is essential. This step strengthens your process to verify a plastic mold parts manufacturers credibility and reduces compliance risks.

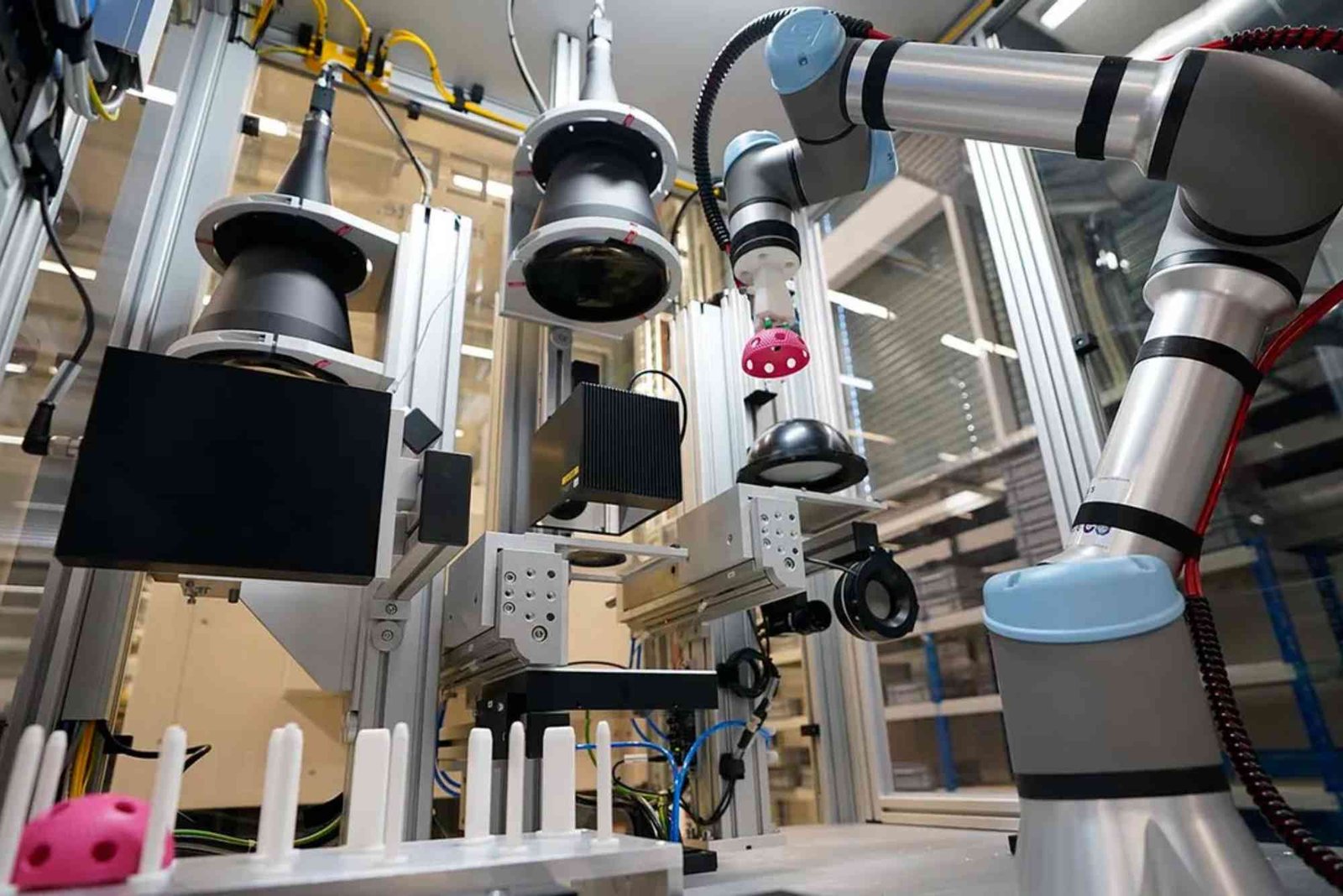

Assess Manufacturing Capabilities and Technology

A credible manufacturer invests in modern machinery and skilled labor. Evaluate their mold design software, CNC machining, and injection molding equipment. Advanced technology ensures precision and repeatability. Ask about material sourcing and testing procedures. These details reveal whether the supplier can meet your technical demands consistently.

Inspect Quality Control Processes

Quality control separates professional manufacturers from unreliable ones. When learning how to verify a plastic mold parts manufacturers credibility, focus on inspection methods, measurement tools, and defect tracking systems. Reputable manufacturers conduct in-process inspections and final audits. They should willingly explain how they prevent defects and handle corrective actions.

Request Samples and Prototypes

Physical samples provide direct evidence of capability. Request mold samples or prototypes before committing to mass production. Examine surface finish, accuracy, and durability. Sample evaluation is a practical way to verify a plastic mold parts manufacturers credibility. Reliable suppliers view sampling as a standard process, not a burden.

Analyze Client References and Reviews

Client feedback offers valuable insights. Ask for references from existing customers in similar industries. Contact them to learn about communication, delivery, and problem resolution. Online reviews and testimonials also help. Consistent positive feedback supports your decision to verify a plastic mold parts manufacturers credibility confidently.

Conduct Factory Audits or Virtual Tours

Factory audits reveal operational reality. Visiting the facility allows you to assess cleanliness, workflow, and workforce expertise. If travel is not possible, request a virtual tour. Audits demonstrate transparency and confidence. This step is one of the strongest ways to verify a plastic mold parts manufacturers credibility before signing contracts.

Evaluate Communication and Responsiveness

Clear communication reflects professionalism. Observe response times, clarity, and willingness to answer technical questions. Credible manufacturers provide detailed quotations and realistic timelines. Poor communication often leads to misunderstandings and delays. Strong communication builds trust and confirms your effort to verify a plastic mold parts manufacturers credibility.

Understand Pricing Structure and Contracts

Unrealistically low prices can signal compromised quality. Review cost breakdowns, tooling fees, and maintenance charges. Transparent pricing aligns with credibility. Contracts should clearly define quality standards, lead times, and penalties. This clarity supports your strategy to verify a plastic mold parts manufacturers credibility effectively.

Check Supply Chain and Material Traceability

Material quality directly affects mold performance. Ask about resin suppliers and traceability systems. Credible manufacturers maintain documentation for raw materials and processes. Traceability ensures accountability and compliance. This factor is often overlooked but crucial when learning how to verify a plastic mold parts manufacturers credibility.

Assess After-Sales Support and Warranty

Reliable manufacturers stand behind their products. Evaluate warranty terms, repair policies, and technical support availability. After-sales support reflects long-term commitment. Manufacturers who offer clear support policies demonstrate confidence in their work and strengthen their credibility.

Compare with Industry Benchmarks

Benchmarking helps validate claims. Compare lead times, defect rates, and pricing with industry averages. This comparison highlights inconsistencies. Using benchmarks refines your approach to verify a plastic mold parts manufacturers credibility and prevents biased decisions.

Use Trusted External Resources

External platforms provide additional validation. Industry directories, trade shows, and procurement platforms offer verified supplier information. You can also explore technical references and standards from trusted retailers and industry leaders for More details at . These resources complement your evaluation process.

For broader insights into evaluating quality-driven choices, you may find this Related Blog articlehelpful, as it explains decision-making based on quality and suitability. You can also explore How To Verify A Plastic Mold Parts Manufacturers Credibility for related industry discussions.

Common Mistakes to Avoid During Verification

Rushing the selection process often leads to errors. Avoid relying solely on online profiles or price comparisons. Skipping audits and references increases risk. A structured approach ensures you properly verify a plastic mold parts manufacturers credibility without assumptions.

How Long Does the Verification Process Take

Verification timelines vary based on complexity. Simple checks may take days, while audits and sampling require weeks. Investing time upfront prevents costly issues later. Patience is key when aiming to verify a plastic mold parts manufacturers credibility thoroughly.

Make Informed Manufacturing Decisions

Learning how to verify a plastic mold parts manufacturers credibility is essential for long-term success. By checking legal status, certifications, quality systems, and communication practices, you minimize risks and improve outcomes. A credible manufacturer becomes a strategic partner, not just a supplier. Take time to evaluate thoroughly and build relationships based on trust and transparency.

FAQs

How do I verify a plastic mold parts manufacturers credibility online

You can verify credibility online by checking business registration, certifications, client reviews, and industry presence. Cross-check information with official sources.

What certifications should a plastic mold manufacturer have

Common certifications include ISO 9001 for quality management and ISO 14001 for environmental standards. Industry-specific certifications add further credibility.

Why are factory audits important when choosing a manufacturer

Factory audits reveal real production capabilities, quality control systems, and workforce skills. They help confirm claims made by the manufacturer.

Can small manufacturers still be credible

Yes, small manufacturers can be credible if they maintain quality standards, transparency, and consistent performance. Size alone does not define credibility.

What red flags indicate an unreliable manufacturer

Lack of documentation, unclear communication, refusal to provide samples, and unrealistic pricing often indicate reliability issues.